Introduction

Architecture is evolving with the rapidly changing world around us which requires a constant reflection and assessment of the past to prepare for future challenges. It has always been a mirror of a community’s creative, engineering, and technological facilities over time. However, in the premise of the 21st century, Architecture is more than just a convention of aesthetic monument-buildings, as nowadays the value of land is touching the sky due to the immense pressure of population growth worldwide.

Any kind of development related to a valuable piece of land holds an added responsibility for maximizing the economic potential of that land. Therefore, architecture can be an essential tool for economic growth in a region.

Financial Growth and Architecture Industry

The Architecture industry is one of the few industries that is continuing to grow despite the current economic conditions. In fact, the Architecture industry is predicted to grow by 3.2% in the next year. There are many reasons for the growth of the Architecture industry. One reason is that the industry is becoming more globalized. With more countries interacting with each other, there is a greater need for architects to design buildings that meet the needs of a global market. Another reason for the growth of the Architecture industry is that there is an increasing demand for sustainable and green buildings.

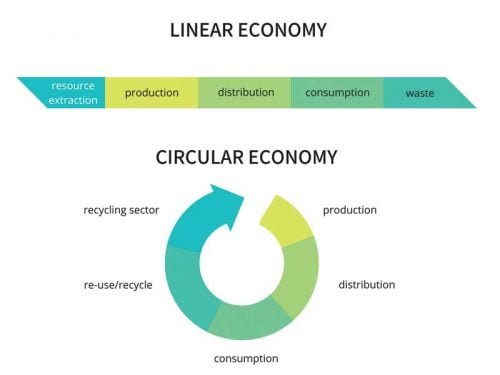

As the world becomes more aware of the need to protect the environment, architects are being called upon to design buildings that are eco-friendly. Finally, the Architecture industry is benefiting from the current trend in the construction industry towards renovating and retrofitting existing buildings. This is especially true in the commercial sector, where businesses are looking to reduce their carbon footprints by renovating their office space.

As the Architectural industry has seen a tremendous amount of growth in recent years, this can be attributed to a number of factors, including the increasing popularity of “green” architecture, the need for more energy-efficient buildings, and the continued growth of the construction industry. As the world becomes increasingly focused on sustainability, architects are being called upon to design buildings that are not only aesthetically pleasing but also environmentally friendly. Green architecture is a rapidly growing field, and many architects are now specializing in sustainable design.

The construction industry is also booming, which is good news for architects. More construction means more demand for architectural services. In addition, the current economic conditions have led to a resurgence in the popularity of home renovation and remodeling. This has created a need for architects who specialize in residential design. The future looks bright for the architectural profession. The combination of increased demand for sustainable design and the continued growth of the construction industry is sure to lead to continued financial success for architects.

There are a number of factors driving the growth of the architecture industry. The first is the increasing population. As the world population continues to grow, there is an increasing demand for housing and commercial buildings. This has led to a boom in the construction industry, and a corresponding increase in the demand for architects. Another factor driving the growth of the architecture industry is the increasing wealth of many nations.

As countries become wealthier, they tend to invest more in construction and development projects. This has led to an increase in the number of high-end, luxury projects that require the services of experienced architects. The architecture industry is also benefiting from the rise of the green movement.

More and more people are becoming aware of the need to conserve energy and resources, and this is leading to an increase in the demand for sustainable, green buildings. Architects who specialize in green design are in high demand as a result. Finally, the rise of technology is also playing a role in the growth of the architecture industry. With the increasing use of computer-aided design (CAD) and other technologies, architects are able to work on more complex projects than ever before.

This has made the profession more attractive to a new generation of designers. The architecture industry is booming and is expected to continue to grow in the coming years. This is good news for architects, who are seeing an increase in demand for their services.

The increasing demand for new and innovative buildings has been a part of the growth. As the world becomes more populated, there is a need for more space. This has led to an increase in the construction of new buildings. The Architecture industry is forecast to grow by 3.2% in the next year. This is a significant increase from the previous year. The industry is expected to continue growing at a similar rate over the next few years.

There are a number of factors that have contributed to the growth of the Architecture industry. The first is the increasing population. As the world becomes more populated, there is a need for more space. This has led to an increase in the construction of new buildings. Another factor is the increasing wealth of people. As people become richer, they want to live in nicer and more expensive homes. This has led to an increase in the construction of luxury homes. The other factor is the improving economy.

When the economy is doing well, there is more money available for investment in the construction of new buildings. Also the increasing demand for office space. As businesses expand, they need more space for their employees. This has led to an increase in the construction of office buildings. One more is the increasing demand for retail space. As the population grows, there is a need for more space for stores and businesses.

This has led to an increase in the construction of shopping malls and other retail spaces. The Architecture industry is expected to continue growing at a healthy rate in the next few years. This growth will be driven by the increasing population and the increasing wealth of people.

The increase in construction and development projects across the globe has also provided a significant amount of growth in the industry in recent years. The construction industry is one of the largest and most important industries in the world. It is also one of the most important industries in the United States, employing more than 7 million people. The construction industry is responsible for the construction of buildings, bridges, highways, and other infrastructure. The construction industry is also a major contributor to the economy, accounting for more than $1 trillion in GDP. The construction industry is projected to grow in the coming years. The US construction industry is expected to grow by 3.6% in 2019 and by 4.0% in 2020.

This growth is driven by a number of factors, including population growth, the increasing number of households, and the growing demand for infrastructure. The population of the United States is expected to grow by 0.7% in 2019 and by 0.8% in 2020. This population growth will drive demand for new housing, as well as for new commercial and industrial buildings. The number of households is expected to grow by 1.5% in 2019 and by 1.6% in 2020. This growth is driven by the increasing number of millennials who are reaching adulthood and forming their own households.

The demand for infrastructure is also expected to grow in the coming years. The US Department of Transportation has estimated that the country will need to invest $1.5 trillion in infrastructure by 2025. This demand is driven by the need to repair and replace aging infrastructure and build new infrastructure to accommodate population growth. The construction industry is expected to benefit from this growth in demand.

The number of construction jobs is expected to grow by 1.1 million between 2018 and 2028. This growth is driven by the increasing demand for housing, commercial buildings, and infrastructure. The construction industry is an important part of the economy. The industry is expected to grow in the coming years, driven by population growth, the increasing number of households, and the growing demand for infrastructure.

The financial growth in architecture has led to an increase in the number of architecture firms, as well as the number of architects employed by these firms. This growth has also led to an increase in the salaries of architects, as well as the fees charged by architecture firms.

The financial growth in architecture has also led to an increase in the number of scholarships and grant opportunities available to aspiring architects. This has made it easier for people from all backgrounds to pursue a career in architecture. The financial growth in architecture has been a positive development for the profession and has resulted in increased opportunities for architects and architecture firms.

Architects are in high demand all over the world, and their skills are needed in many areas. The field of architecture is growing at a rapid pace. In 2018, the average salary for an architect was $76,000. This is a significant increase from the average salary of $60,000 in 2010. The demand for architects is expected to continue to grow as the world population increases and more people are moving into cities.

Architects who can design buildings that are connected to the internet and are energy-efficient are in high demand. Cities are looking to become more efficient and sustainable, and architects are key to making this happen. The financial growth in architecture is good news for those in the field. It is expected to continue to grow in the years to come, and there are many opportunities for those who are qualified.