Table of Contents

Introduction

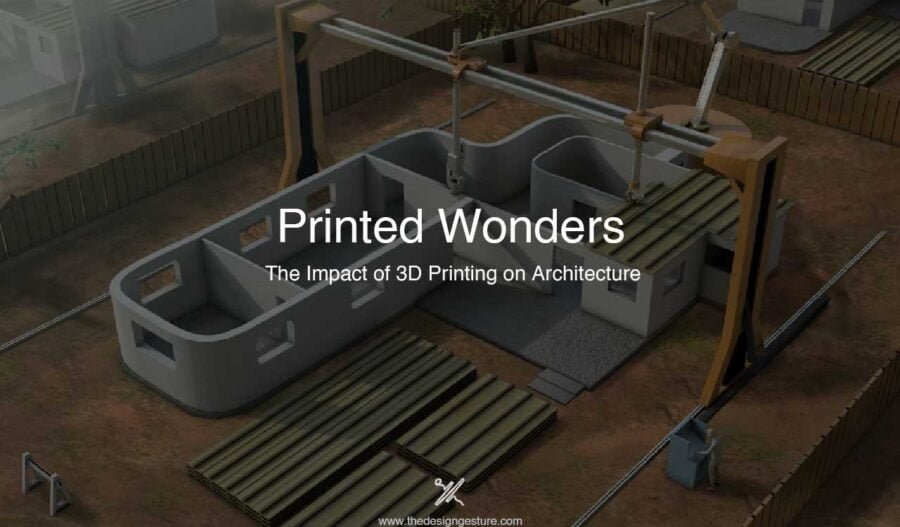

The extraordinary gift of 3D printing technology has been bestowed on the world of architecture by the quick rate of technical growth. In recent years, 3D printing has made significant strides across various industries. The integration of 3D printing in architecture has shifted how architects approach building design, construction procedures, and even sustainability. 3D printing’s ability to expedite manufacturing processes enables architects to create elaborate structures faster and more precisely than ever before.

The Basics of 3D Printing

In the sphere of contemporary architecture, we have witnessed the fusion of two transformative concepts: sustainability and digital technologies. This dynamic duo is reshaping architectural practices beyond mere representation and into the very core of design and manufacturing processes. Architects are now familiar with terms like parametric design, adaptive design, Building Information Modeling (BIM), nanomaterials, and, notably, 3D printing. This multifaceted technology is also known as additive manufacturing and has altered the world of design. It operates by meticulously crafting 3D objects layer by layer, following precise digital models. While it initially gained prominence for rapid prototyping, 3D printing has matured to the point where it can produce fully functional end-products.

Types of 3D Printing in Architecture

In construction and architecture, three main 3D printing technologies have emerged. Firstly, robotic arm extruders, also known as contour crafting, function similarly to desktop Fused Deposition Modeling (FDM) 3D printers. They use rails to guide a robotic arm that extrudes concrete material to build structures layer by layer, particularly for large-scale projects. Another method akin to industrial 3D printing processes is Sand 3D Printing, pioneered by architect Enrico Dini’s D-shaped 3D printer. This technique applies layers of sand powder and solidifies them using a binder, offering a unique departure from traditional construction.

For structures requiring robustness, Wire Arc Additive Manufacturing (WAAM) technology combines an industrial robot with a welding machine, effectively turning it into a 3D printer for creating durable metal architectural components. These 3d printing construction methods coexist with established techniques like Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). FDM uses heated thermoplastics for precise structures; SLA cures liquid photopolymer with a UV laser for intricate designs; and SLS fuses powdered material particles with a laser for sturdy parts suitable for prototyping and production. Together, these diverse 3D printing technologies redefine architecture and construction, offering precision, efficiency, and durability as their hallmarks.

The Benefits of 3D Printing

3D printing is rapidly revolutionizing construction with its numerous advantages. It significantly accelerates production, constructing homes in a day. These automated printers reduce human errors and efficiently use materials, minimizing waste and saving costs. Moreover, they enable innovative, intricate, and geometric designs that were once challenging with traditional methods. Architects can present physical 3D visuals to clients, ensuring personalized structures and addressing concerns. Large-scale 3D printers are even constructing entire buildings, reducing costs and timelines. Sustainability is a priority in modern architecture, and 3D printing aligns perfectly by using eco-friendly and recycled materials, reducing environmental impact, and optimizing resource use.

Furthermore, 3D printing aids in disaster relief and affordable housing, swiftly providing shelter where needed. It also plays a vital role in architectural restoration and preservation by creating precise digital replicas. Material advancements introduce creative options like self-healing bio-concrete, reducing maintenance costs and increasing building lifespan. Lastly, the digital nature of 3D printing fosters global collaborative design, enabling teams worldwide to work together seamlessly and produce diverse and inclusive architectural designs.

Boundaries of 3D Printing

While 3D printing presents numerous opportunities, it also comes with challenges. Regulatory bodies and governments are working to establish standards and safety guidelines for 3D-printed structures. Ethical considerations, such as intellectual property rights and the responsible use of 3D printing technology, are also being discussed within the architectural community.

3D Printing in Action

Architects wield a versatile toolkit through 3D printing. Its applications span historical preservation, cost-effective housing solutions, parametric designs for energy efficiency, and rapid responses to emergencies. Beyond functionality, architects embrace 3D printing as a medium for artistic expression, seamlessly merging art and architecture. From art installations to furniture design, these diverse applications underscore the technology’s transformative potential within the field. Now, let us delve into the projects reshaping construction and design through 3D printing technology.

Apis Cor House

A pioneering achievement by 3D printing construction company Apis Cor saw the completion of Russia’s first on-site 3D printed house in just 24 hours. The house, designed in a unique circular shape, was constructed using Apis Cor’s mobile 3D printer, known for its precision and transportability. The house, with a floor area of 38 square meters, features an unconventional circular design with right-angle protrusions. Despite being built during the coldest time of the year, it necessitated the creation of a protective tent to maintain suitable temperatures for the concrete mixture used as “ink.”

The house’s roofing system, made with LOGICROOF polymer membranes and LOGICPIR hard polystyrene, can withstand heavy snow loads while remaining highly insulated. Additionally, innovative insulation materials and techniques contribute to a comfortable microclimate within the residence. Impressively, the entire project cost only $10,134, highlighting the cost-effectiveness of 3D printing construction. The Apis Cor House marks a significant advancement in 3D printing construction technology, demonstrating its potential for efficient and affordable home construction.

Tecla House

In Massa Lombarda, Italy, Mario Cucinella Architects and 3D printing specialists WASP have joined forces to create Tecla, a groundbreaking eco-friendly housing prototype. Named after a fusion of “technology” and “clay,” this home stands out for its use of 3D-printed clay sourced from a nearby riverbed. This transformative home features two interconnected dome-shaped structures, whose exteriors are formed by stacking an impressive 350 layers of 3D-printed clay. These undulating layers serve as an efficient thermal insulator and offer adequate structural stability. The compact interior maximizes functionality and comfort. Additionally, Tecla’s roof has strategically placed circular skylights for ample natural light, creating an inviting and organic ambiance.

Tecla stands out through its utilization of a sophisticated multilevel modular 3D printer equipped with twin synchronized arms, each with the capacity to print within a 50-square-meter zone. This high-tech marvel empowers the swift assembly of housing modules in a mere 200 hours, all the while significantly curbing energy consumption and waste generation. The project seamlessly combines well-established building methods with modern engineering, producing homes designed for climate health and environmental sustainability, as well as being capable of adjusting to the shifts of changing weather conditions. This approach acts as a proactive response to global climate emergencies and satisfies the growing need for green, flexible housing solutions.

MX3D Bridge

A stunning stainless steel 3D-printed bridge stretches gracefully across Amsterdam’s Oudezijds Achterburgwal canal in the Red Light District. A Dutch studio, Joris Laarman Lab, collaborated with MX3D, an Arup engineering firm, to create a 12-meter-long pedestrian bridge. The bridge features an elegant, curved S-shaped design with intricate lattice-style perforations on its balustrades, all meticulously crafted using advanced parametric modeling software.

The bridge took shape through the gradual addition of molten metal, with robotic arms fitted with welding equipment meticulously printing layer upon layer of the structure. The bridge was constructed with 4,500 kilograms of stainless steel, a material that was 3D-printed by robots at a factory over six months. Later, it was lifted into place over the canal. Additionally, the bridge is equipped with sensors that allow it to collect data for performance and maintenance, advancing data-centric design approaches for future projects.

Traditional House of the Future

In China’s Nanlong Village, professors John Lin and Lidia Ratoi from the University of Hong Kong embarked on the Traditional House of the Future project. They combined 3D printing with an old wooden house, reinvigorating it with inventive design. After scanning and deconstructing the original structure, 3D-printed walls extended the living space, creating new rooms. Once the 3D-printed elements were in place, the original wooden structure and tiled roof were reintegrated into the house, preserving its heritage.

The Traditional House of the Future project combines 3D printing with ancient architecture, demonstrating its potential for flexible renovations. Beyond that, it champions the fusion of technology with local building practices and sustainability, reimagining old structures to suit modern lifestyles. This project redefines cultural preservation by drawing inspiration from rural China’s innovative vernacular house renovations. It’s a remarkable blend of tradition and technology, offering exciting possibilities for adaptive architecture that transcends time.

Airlements Project

Researchers at ETH Zürich and FenX AG are using cement-free mineral foam made from recycled waste in large-scale robotic 3D printing to create monolithic, lightweight, and instantly insulated wall systems. The project is named Airlements and features technology that optimizes thermal performance reduces energy consumption, and allows for future material recycling.

The project features a 2-meter-tall wall prototype composed of four 3D-printed segments, each weighing 25kg and printed in under an hour. The corrugated texture of each piece contributes to the overall strength and structural integrity of the final structure. These segments can be filled with mineral foam and sealed with cementless plaster to serve as non-structural exterior walls, with potential applications expanding as research progresses. As the research advances, emphasis will be placed on improving the load-bearing capacity of these elements and refining the precision of the 3D printing system.

Systems Reef 2

Systems Reef 2 is a revolutionary 3D-printed air conditioning system engineered by Australian architectural firm BVN in partnership with the University of Technology Sydney. The system reduces carbon emissions by an astounding 90% when compared to its traditional air conditioning counterparts, thanks to its unique incorporation of recycled plastic.

In pursuit of enhanced comfort for occupants beneath the system, the design team drew inspiration from frogs, known for breathing through their skin. Diverging from traditional designs, Systems Reef 2 boasts a unique structure with branch-like tubing, eradicating the presence of obstructive, sharp corners that typically impede airflow and escalate energy consumption. Systems Reef 2 also incorporates small pores that efficiently disperse cool air, creating a mist-like effect in the area below. Offering flexibility, efficiency, and sustainability, it presents a compelling showcase of 3D printing’s potential in the construction sector.

The Future of 3D Printing in Architecture

The future of 3D printing in architecture holds immense promise. In architecture, 3D printing empowers architects with unprecedented design freedom, cost-effective prototyping, and sustainable construction solutions, influencing the way buildings are conceived, constructed, and experienced.

Researchers are exploring the integration of robotics and artificial intelligence to enhance precision and efficiency. Advancements in 3D-printed construction materials may lead to more sustainable, energy-efficient, and adaptable structures. These advantages extend beyond construction and are applicable across various industries. Businesses can incorporate different 3D printing technologies, including plastic, resin, and metal printing, to stay competitive. However, challenges like regulatory approvals, quality control, and integration into existing construction processes must be addressed. Architects and researchers are actively working to overcome these obstacles, ensuring an eco-conscious future for architecture.

Conclusion

3D printing technology stands as a profound force reshaping the landscape of architecture. Its impact spans from expediting rapid prototyping to facilitating sustainable building practices and even contributing to humanitarian endeavors. We have already seen the enormous benefits of 3D printing in countless areas, but its potential is not yet realized. This game-changing technology will continue to give architects, engineers, and designers the power to create structures that are not only visually stunning but also exceptionally sustainable, cost-effective, and universally accessible. Embracing 3D printing in architecture transcends being a mere trend; it represents a fundamental paradigm shift that will undeniably define the industry’s future.