When it comes to selecting a Monarch hydraulic pump, it’s crucial to focus on specific factors to ensure you make the right choice for your unique requirements. These pumps are essential in various industries for their reliability and efficiency. Let’s dive into the top tips for selecting the ideal pump for your needs, weaving in real-life scenarios and an analytical approach to guide you through the process.

Table of Contents

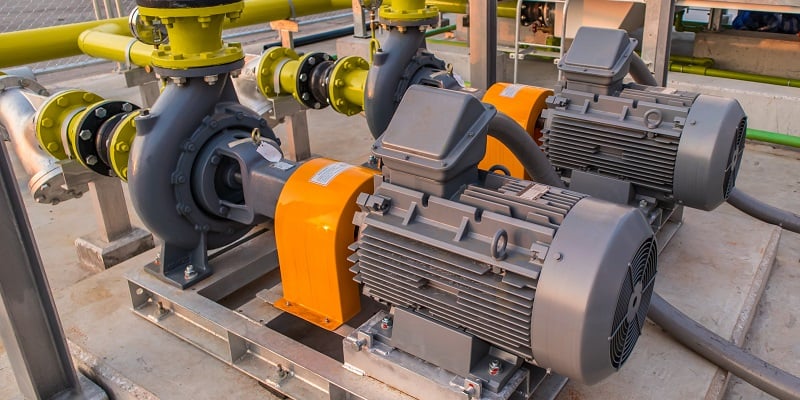

Understanding Your System’s Requirements

Before you even begin to look at different pumps, it’s essential to fully understand the specific needs of your system. For instance, consider the story of a local construction company that once overlooked this step. They ended up with a pump that was too powerful for their machinery, leading to frequent breakdowns and costly repairs. To avoid such a scenario, evaluate your system’s pressure, flow rate, and power source requirements. It’s not just about getting a pump; it’s about getting one that fits seamlessly into your system.

Considering the Brand’s Reputation and Support Services

The brand behind a hydraulic pump plays a crucial role in your decision. A friend in the manufacturing sector once shared how choosing a pump from a reputable brand saved them during an unexpected breakdown. The brand’s responsive customer service and availability of spare parts made the repair process swift and less disruptive. When selecting your Monarch hydraulic pump, consider the brand’s history, customer service quality, and the availability of technical support and spare parts.

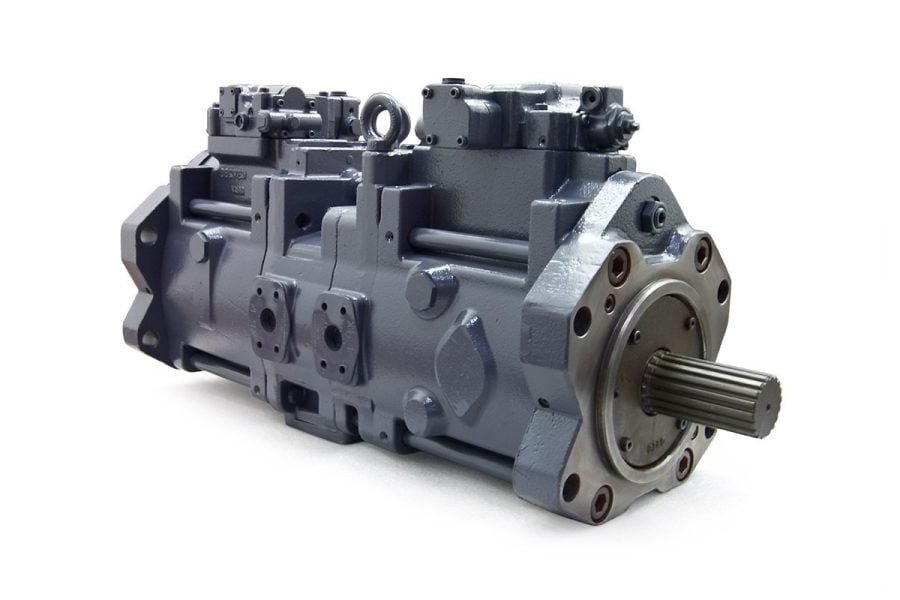

Evaluating Hydraulic Pump Quality and Durability

The longevity and reliability of hydraulic pumps are non-negotiable. I recall a farming client who opted for a cheaper, lower-quality pump to save costs. Unfortunately, this decision backfired when the pump failed during a critical harvesting period, causing significant downtime and loss of income. This experience underscores the importance of not compromising on quality. Look for pumps made from robust materials and designed for durability, especially if they will be used in demanding environments.

Analyzing Total Cost of Ownership

While the initial cost is a significant factor, the total cost of ownership (TCO) is equally important. TCO includes purchase price, maintenance costs, operating costs, and potential downtime costs. For example, a hydraulic pump with a lower initial cost but high maintenance requirements can end up being more expensive in the long run. An analysis of TCO offers a more comprehensive understanding of the pump’s long-term financial impact.

Compatibility with Existing Systems and Future Needs

Finally, think about how the hydraulic pump will fit into your current system and whether it can adapt to potential future changes. A colleague in the mining industry once faced a challenge when their existing pump could not be integrated with upgraded machinery, leading to additional expenses. Ensure the pump you choose is compatible with your current setup and has the flexibility to accommodate future upgrades or expansions.

In conclusion, selecting the right hydraulic pump requires a thoughtful approach, considering your system’s specific needs, the pump’s quality, the brand’s reputation, TCO, and compatibility with your existing and future systems. By following these tips and learning from real-life experiences, you can make an informed decision that ensures efficiency, reliability, and cost-effectiveness for your hydraulic system needs.